What is a stretch hood?

A stretch hood is a tube of film sealed on one end, which is stretched over a palletised load to secure the contents to the pallet.

The film is cut to the appropriate length, heat sealed on the top end, and gathered on four ‘fingers.’ These fingers stretch the film in the horizontal (transverse) direction until the film dimensions are slightly larger than the load dimensions, then draw the stretched film down over the pallet, unrolling it as they go. By varying the unrolling rate, a degree of vertical (machine) direction stretch can be obtained to better hold the load on the pallet. At the bottom of the pallet, the fingers release the film, which typically wraps under the pallet bottom.

Why choose stretch hoods over other palletising methods?

Stretch hoods offer the most comprehensive list of palletising benefits, including:

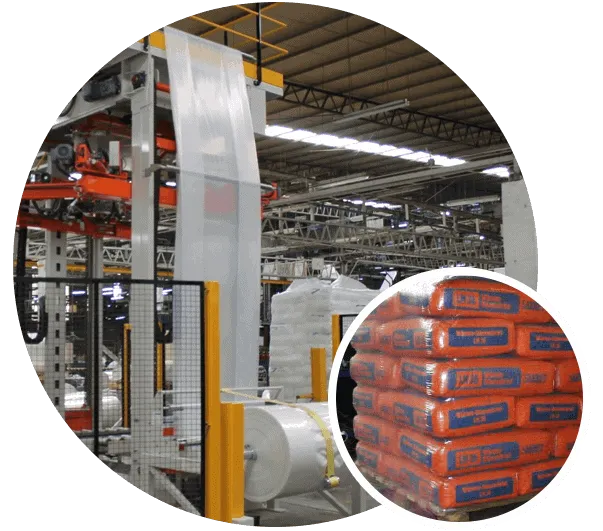

Logistics management – The stretch hood process is more efficient (100 loads per hour for stretch hood vs 60 loads per hour for stretch wrap).What market segments and applications use stretch hoods?

Stretch hoods are one of the fastest growing pallet stabilisation and packaging systems. Load stability and the flexibility to control elasticity and holding force make stretch hoods ideal for palletising many applications – from empty PET bottles (high elasticity and low holding force) to cement bags (low elasticity, high holding force).

Building materials and heavy-duty shipping sacks in particular have seen a rise in popularity of stretch hoods. Specific applications include: bricks, stones, shingles, bagged concrete, and bagged resin. And, appliances have also seen high growth of stretch hoods (at the expense of corrugated board).

What are the film requirements for stretch hood?

The stretch hood is a demanding application, requiring good tear and/or puncture resistance and a balance of holding force and elasticity. This, of course all starts with the quality of resins and finding the right formulation for specific loads.

The coefficient of friction (COF) is critical for stretch hoods and must be low enough that the hood will slide over the load without wrinkling or tearing as it is applied. Conversely, the COF must be high enough that the film does not slide off the machine fingers too easily, so the hood can be stretched in the vertical direction.

Stretch hood films are typically three-layer systems – two outer skin layers and the core.